The lab is one of those groups that have substantially contributed to employing micro and nanoelectrochemistry to investigate processes at the interface of electrodes. Schuhmann’s group has developed advanced electrochemical techniques using micro and nanoprobes such as single-entity analysis (e.g., nanoparticles), scanning electrochemical microscopy (SECM), scanning electrochemical cell microscopy (SECCM) and scanning droplet-cell (SDC).

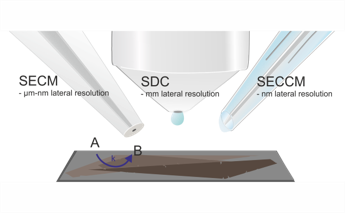

Electrochemical processes occur on the extension of some micro-nanometer at the electrode/electrolyte interface. SECM and SECCM have developed powerful techniques for interrogating charge transfer events since they provide spatially resolved information (electrochemical maps) about redox activities. In the case of SECM, micro and nanoelectrodes are positioned some µm from the sample surface. The SECM tip indirectly probes an interface process by recording physical quantities (current or potential). The scanning droplet-based techniques (SECCM and SDC) working principle is based on the confinement of the electrochemical cell between the investigated surface (working electrode) and a hanging droplet coming out from an aperture on the tip. While SECCM uses a droplet protruding from the aperture of a nanopipette, the SDC droplet comes out from an mm-aperture of a larger compartment. SECCM and SDC have been explored as high throughput electrochemical analyses to screen materials composition of materials library and high entropy alloy towards electrocatalysis. In parallel, Schuhmann’s group has employed SECM and SECCM to elucidate charge transfer kinetics and mechanisms in bioelectrochemistry, battery sciences, bioelectrocatalysis, and electrocatalysis.

One key to improving battery performance is understanding the process occurring at the interphases. The information obtained from the traditional techniques is macroscopic and, due to the compartment cell arrangement, addressing the role of individual processes is often complex. For these reasons, investigating electrochemical processes at a half-cell has shown a straightforward approach and use of advanced techniques with highly surface-sensitive to gain insights into the lateral arrangement of the surface. Our group has high expertise in applying SECM and SDC to study liquid-liquid and solid-liquid interfaces on battery. The group was the first to investigate the charging/discharging of battery materials in an open half-cell by SECM in a glove box. In the last years, scanning electrochemical probe microscopies (SECM and SECCM) were successfully employed in the field of LIBs to study the kinetics of charge transfer and the battery interface properties, demonstrating to be unique and powerful analytical tools

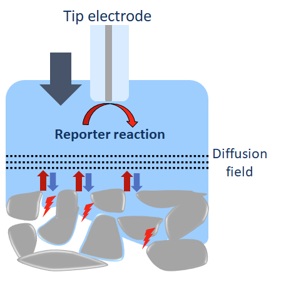

The conversion of a reactant within an electrocatalytic process imposes changes to the catalyst microenvironment. One well known effect is the local modulation of the electrolyte pH value during proton-coupled electron transfer sequences. Our group utilizes scanning electrochemical microscopy methods to characterize such localized changes under reaction conditions. For this purpose, we developed setups, which do not only allow the fabrication of metal-based micro- or nanoelectrodes, but also enable a positioning of that miniaturized probes in the diffusion field of operating electrodes. Here, shear-force based approach methods allow us to achieve probe-substrate distances of a few hundred nanometers.

The employment of nanoelectrodes for electrochemical measurements are overcoming several limitations of bulk measurement techniques, for example slow diffusion and the so-called film effect (change in the local pH, overlapping diffusion fields, and more). The investigation of single nanoparticles (NPs) at carbon-based nanoelectrodes (CNEs) is giving a direct insight into the intrinsic activity of the investigated assembly as well as its structural evolution at the atomic scale when combined with identical location TEM. Our group was developing a unique placing strategy of single NPs onto CNEs under SEM control, which utilizes a robotic arm for the pick and placement procedure.